Top 4 Trends in Nutraceutical Packaging

On-the-go formats, pre-measured doses, and single-use doses are examples of packaging-driven innovations that facilitate a healthy, profitable nutraceutical market. The market for nutraceuticals is experiencing dynamic growth and revenue opportunities. Numerous health advantages are provided by these fortified foods and dietary supplements. The major players are concentrating on cutting-edge packaging methods to maintain competition for innovation growth in the pharmaceuticals and food and beverage industries. Cognitive health, weight management, and overall health and well-being are more important to younger consumers. This has a significant impact on the expansion of overall demand for nutraceuticals and functional foods. In parallel, younger people’s demand for novel packaging for these foods is steadily increasing. the largest customer base for dietary supplements, functional foods, and nutraceuticals.

Top consumer trends that will drive demand for nutraceutical packaging:

Sustainable packaging is a must for the nutraceutical industry’s younger customer base. Nutraceuticals are in high demand among youth due to their increased resistance to chronic diseases and other physical advantages. The primary factor for packaging companies that deal with nutraceutical packaging is a strong demand for herbal products, isolated nutrients, diet pills, genetically modified foods, and processed foods like cereals, soups, and beverages. To ensure that they arrive in perfect condition and have a longer shelf life, all of these products must be handled with care. Here are four major packaging trends that have been observed in nutraceuticals.

1. Keeping counterfeits at bay

The Association for Packaging and Processing Technologies’ report indicates that counterfeiting is expanding at a worrying rate. When it comes to dealing with products like nutraceuticals, which are used by a lot of customers, a brand’s dependability is very important. When there is competition in the industry, this becomes even more important. To ensure the safety of their products, manufacturers are relying on a number of cutting-edge packaging methods like hologram-enabled authentication, anti-diversion codes, individual fingerprints, and invisible inks and technologies.

2. Everything depends on safety

Manufacturers are encouraged to use eye-catching and inventive packaging to attract consumers’ attention because there are so many nutraceuticals available each year. When it comes to keeping a packaged product’s aesthetic appeal intact, adding security features can be challenging. The search for and purchase of flexible packaging to shield products from oxidation, moisture, dehydration, microbes, bacteria, and other threats is a major trend in this market. This kind of packaging is great for transportation and storage because it is lighter and saves space.

3. A desire for responsible living

Manufacturers in the market have become more cautious as environmental and long-term effects of using certain packaging materials have become more of a concern. Consumers are making better decisions when they shop for a variety of goods, including nutraceuticals, thanks to the growing popularity of lifestyles of health and sustainability (LOHAS) and sustainable living. Green packaging solutions are a significant market trend. For instance, the nutraceutical packaging industry has made a clear transition from plastic to paper. Numerous beverage companies are attempting to innovate despite the fact that plastic bottles continue to dominate the packaging industry.

4. Adapting to increasing demands from customers

Nutraceutical packaging manufacturers must take into account the ever-changing requirements of consumers. Trends like these are steadily rising in tandem with the demand for child-safe materials and labeling that is simple to read:

- Mobile accessibility: Packaging designed for travel that makes storage simple.

- One-time use: Packaging with a pre-measured dosage can be used or discarded.

- Popularity of blister packs: Blister dosages of small food items, pharmaceuticals, and other consumer goods that have been pre-measured.

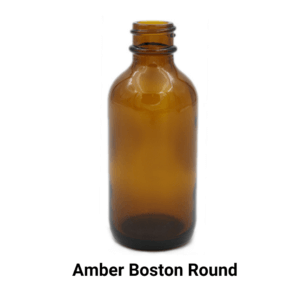

For supplements, consumers prefer plastic packaging like jars, canisters, and bottles; for capsules, liquids, tablets, and powders, they prefer glass bottles. Customers also consider the kind of outer boxes, seals, labels, tamper-evident locks, closures, desiccants, package inserts, and internal cotton, among other things, in addition to the materials.

Conclusion

Manufacturers in the global nutraceutical packaging market are expected to benefit from rising demand for low-cost, antimicrobial, and non-toxic goods. Major market players are focusing on improving the materials and designs of packaging to meet the shifting demand of consumers for convenience in terms of dosage, storage, and dispensing. Companies are focusing on creating distinctive packaging, shapes, and materials to differentiate their products on the shelf for customers in order to maintain market competition. In the not-too-distant future, it is anticipated that manufacturing and government sustainability initiatives will also boost growth opportunities.

TALK TO A PACKAGING CONSULTANT

Silver Spur offers a wide range of plastic and glass bottles. A consultation with a Silver Spur packaging expert could help tailor the right solution for your product. Get started with us today and find the right solution for your nutraceutical packaging needs.

Flint

Flint

Amber

Amber

Cobalt Blue

Cobalt Blue

Green

Green

White

White

Glass dropper bottles allow you to store all kinds of mixtures, medicines, and chemicals. Glass dropper bottles are primarily used to store and transport items like eye drops, liquid medications, CBD products, essential oils, ear care medications, hair care products, and other hygiene products such as soap or shampoo. Clever up-cyclers all over the world have also found ways to repurpose these versatile, safe bottles to hold just about anything. What makes them so useful though?

Glass dropper bottles allow you to store all kinds of mixtures, medicines, and chemicals. Glass dropper bottles are primarily used to store and transport items like eye drops, liquid medications, CBD products, essential oils, ear care medications, hair care products, and other hygiene products such as soap or shampoo. Clever up-cyclers all over the world have also found ways to repurpose these versatile, safe bottles to hold just about anything. What makes them so useful though?

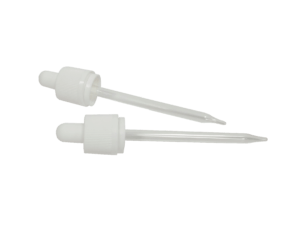

What is your product going to be used for and what is the consistency of your product? For liquid products consider the use of our

What is your product going to be used for and what is the consistency of your product? For liquid products consider the use of our

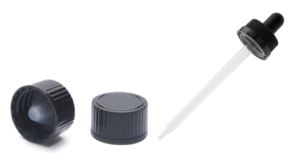

#3 THREAD -This is the section of the finish that has a spiral shape. It is where the closure is twisted to seal the container. The size of the bottle neck determines the thread – standards range from between 5 threads per inch to 12 threads per inch. A well engineered thread will protect the bottle contents by keeping them fresh and free from being tampered with which can lead to product damage.

#3 THREAD -This is the section of the finish that has a spiral shape. It is where the closure is twisted to seal the container. The size of the bottle neck determines the thread – standards range from between 5 threads per inch to 12 threads per inch. A well engineered thread will protect the bottle contents by keeping them fresh and free from being tampered with which can lead to product damage.